Another masterpiece project for SKILLED in the segment of frozen food. This time again for French Fries!

After completing several installations in US and Canada, this top world leader group for frozen food decided to give again a chance to SKILLED in his first installation in Latin America. The company decided Argentina to be their Headquarter where to start business activities in South America and didn’t hesitate to appoint SKILLED as the most valid partner for their end of the line. In a location as is the province of Mendoza, beautiful scenario where the flat Argentinian Pampa encounter the heightest peaks of the Ande’s, SKILLED accepted this challenging project thanks also to the possibility to offer local After Sales Services in a continuous growing market as is Latin America.

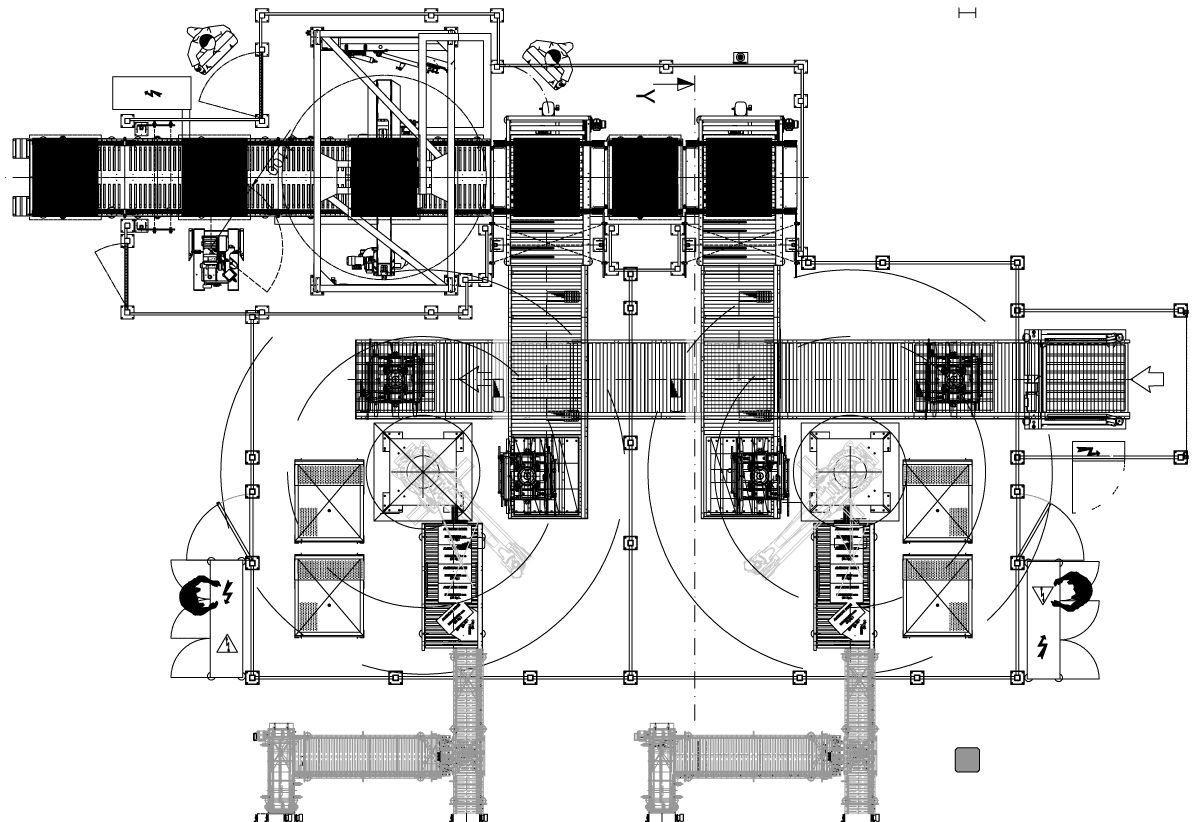

The solution SKILLED proposed to palletize the first 4 production lines is about 2 articulated arm robots capable each to absorb the production of 2 lines each. The client may decide to use either pallets for local market or either pallets for export purposes and the system is capable to process both at the same time as well to place slip sheets and tier sheets where necessary in the pallet.

The solution is complete of rotary arm stretch wrapper equipment and labeling equipment as well to maintain traceability of the products along the production line. Next step from the customer is the automatic transfer of the stretched and labeled pallet from the palletizing area to the cold storage and SKILLED is ready to take the call by proposing some AGV applications tailored to respond to the specific needs the client is proposing.

The solution is complete of rotary arm stretch wrapper equipment and labeling equipment as well to maintain traceability of the products along the production line. Next step from the customer is the automatic transfer of the stretched and labeled pallet from the palletizing area to the cold storage and SKILLED is ready to take the call by proposing some AGV applications tailored to respond to the specific needs the client is proposing.

Argentinian grilled meat (asado) with a good glass of Mendoza wine and a side dish of local French Fries…, what a perfect combination of styles!