A Global leader in the tire market recently decided to go for SKILLED end of the line solution for one of his biggest European plant. Listed on top 5 largest tires manufacturers in the world and producing an infinite range of tires per different categories and applications of vehicles, in this European plant they produce tires for big moto-monsters as well as commercial motorcycle vehicles. When looking a big powerful Harley Davidson on a sunny summer day climbing up hills and mountains all around Europe… well… that Harley probably got its tires handled by SKILLED systems.

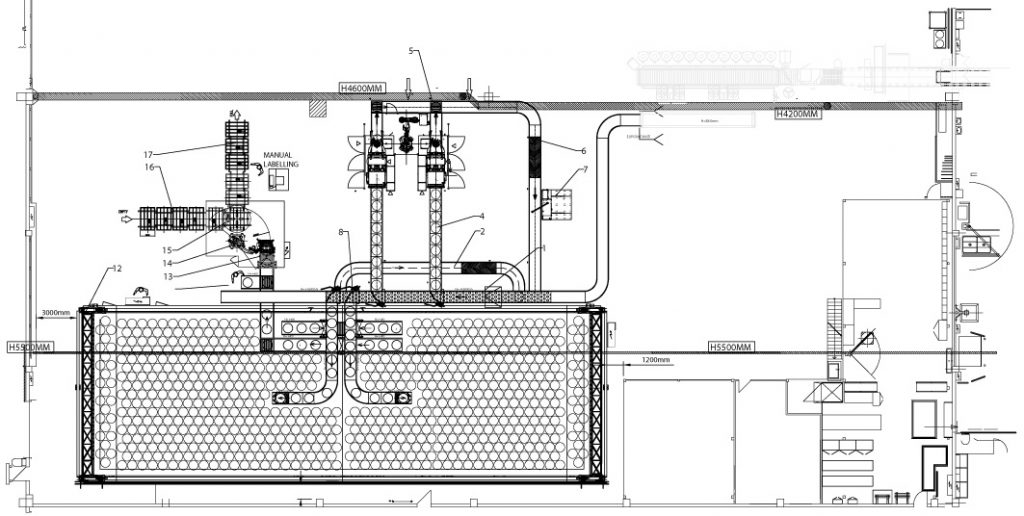

The customization of the system has practically zero limits and it consists in a buffer storage on the floor made of 2 gantries each with 2 heads creating the necessary numbers of tires for different SKU’s to fill up the different material carriers. In within the proposed system also 2 testing machines have been implemented as a demostration of the versatility and flexibility Skilled has to offer to this peculiar market.

The buffering storage area receive the tires from different production lines. All tires are identified by reading systems and their traceability is ensured all along the movements and programmed positions. A human friendly interface is provided as part of the system to allow easy monitoring and assignment of production lots to the shipping area.

At the shipping area a 6 axis – 500 kgs loading capacity articulated robotic arm is capable to handle with maximum care all articles in the storage.

A unique gripper, valid for all different SKU’s is capable to create piles of tires and introduce the same on dedicate material carriers.

The solution is capable to work 24/7 with practically no human intervention and the target is now to extend and repeat the same positive experience in other moto department as well as on other bigger tires departments.